ASAHI PLATING VIET NAM.,. JSC

Factory 1: Lot 6-2 Quang Minh Industrial Park , Quang Minh Town, Me Linh Dist, Ha Noi City. Tel 093 200 6371

Factory 2: Lot CN12-01, Yên Phong Industrial Park , Thụy Hòa Commune , Yên Phong Dist, Bắc Ninh Province. Tel 091 589 3753

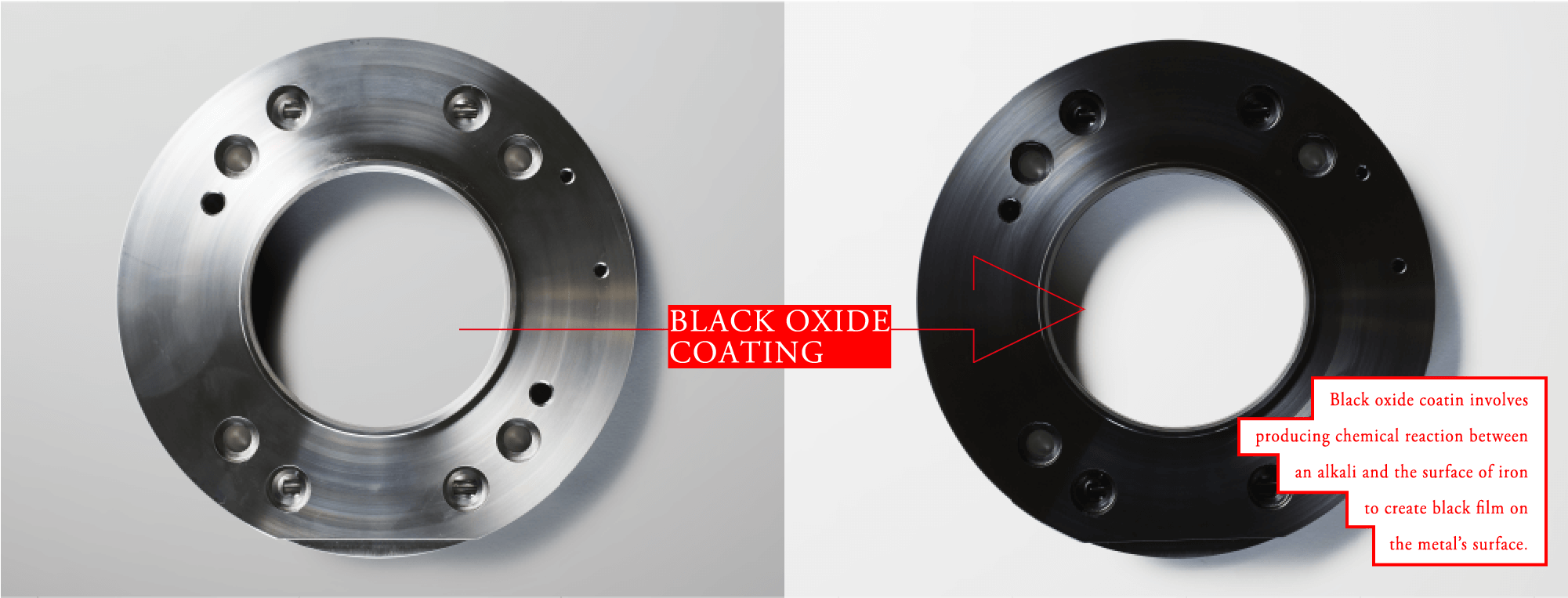

Hard Anodizing

TYPE III: HARD COAT ANODIZING

(Low Temperature, Hard Anodizing)

Sulfuric acid anodizing has been defined as “an electrochemical process that intentionally forms a porous anodic oxide on aluminum”. This oxide, an integral part of the metal, is formed when a current is applied to the aluminum parts in a sulfuric acid anodizing bath.

Type III (hardcoat) anodizing is an anodizing process that forms an extremely hard, abrasion resistant, porous oxide on aluminum. It is generally referred to as an “engineering hardcoat” due to the fact that the oxide has been found to be suited for applications where the hardness and increased oxide thicknesses are an advantage. Aluminum cookware, military applications and a myriad of other uses have made Type III anodizing very popular.

Type III (Hardcoat) anodizing differs from the typical Type II room temperature anodizing in a number of ways:

The anodizing bath parameters for Type III (hardcoat) anodizing are similar to type II (room temperature) anodizing in that the acid and aluminum concentrations can be virtually the same. The difference becomes apparent when you consider the other operating parameters.

Type III anodizing is performed in a sulfuric acid bath containing 180-200 grams per Liter of acid and a small amount of dissolved aluminum. The operating temperature is controlled between 28-32º F but in some instances an acceptable oxide can be achieved at slightly higher temperatures. Current densities can range from 24-40 amps per square foot (ASF), but commonly are run at 24-30 ASF.

Type III anodizing is performed in a sulfuric acid bath containing 180-200 grams per Liter of acid and a small amount of dissolved aluminum. The operating temperature is controlled between 28-32º F but in some instances an acceptable oxide can be achieved at slightly higher temperatures. Current densities can range from 24-40 amps per square foot (ASF), but commonly are run at 24-30 ASF.

The power supply is a DC rectifier. The aluminum part being anodized is made the anode (or positive pole) in the system. The most efficient cathodes (or negative pole) are 6063t6 aluminum.

Current is applied to the system for a prescribed time, and at the desired current density to achieve the oxide thickness required (oxide thicknesses can range from 0.7 mil to 3.0 mils). The resulting porous oxide can then be colored or sealed but limitations on final color will determined by the oxide produced and color used.

Hardcoat anodize, while usually done in a sulfuric acid based electrolyte, is much thicker and denser than the more conventional sulfuric anodize. Hardcoat is specified for aluminum components subject to extreme wear applications where superior abrasion resistance is needed, or corrosive environments where a thicker, harder, more durable coating is necessary.

It can also be valuable where enhanced electrical insulation is required. Since hardcoat anodize can be built up to several thousandths in some cases, it makes this type of anodize a candidate for salvaging worn or mis-machined components.

Hard Anodize Features:

- Improved wear resistance

- Non-conductive

- Can repair worn surfaces on aluminum

- Improve parts surface for slide applications

- Can be black dyed; other colors less decorative

- Finish is harder than tool steel

- Can be ground or lapped

Hard Anodize Applications:

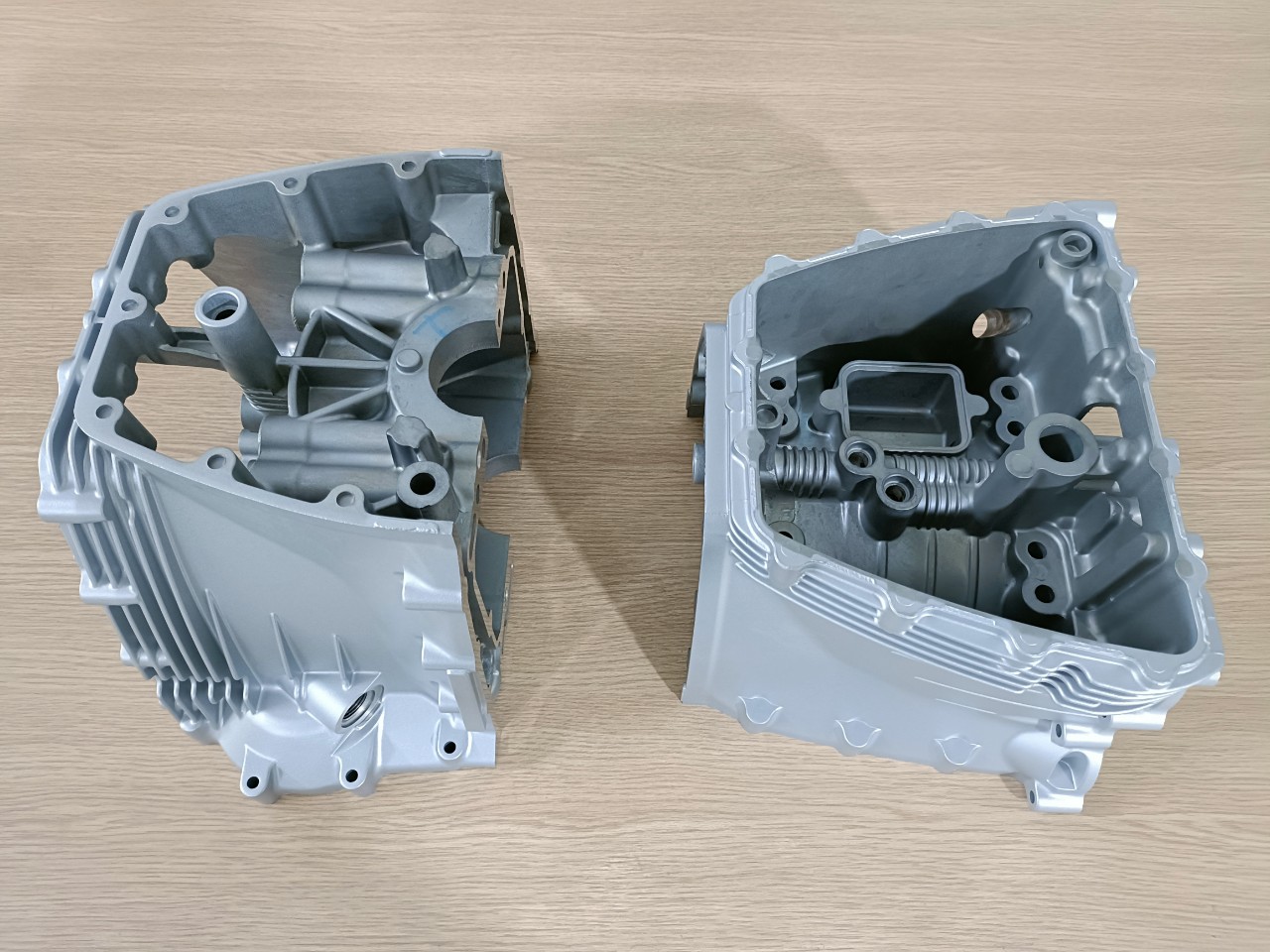

- Valves

- Pistons

- Sliding Parts

- Hinge Mechanisms

- Cams

- Gears

- Swivel Joints

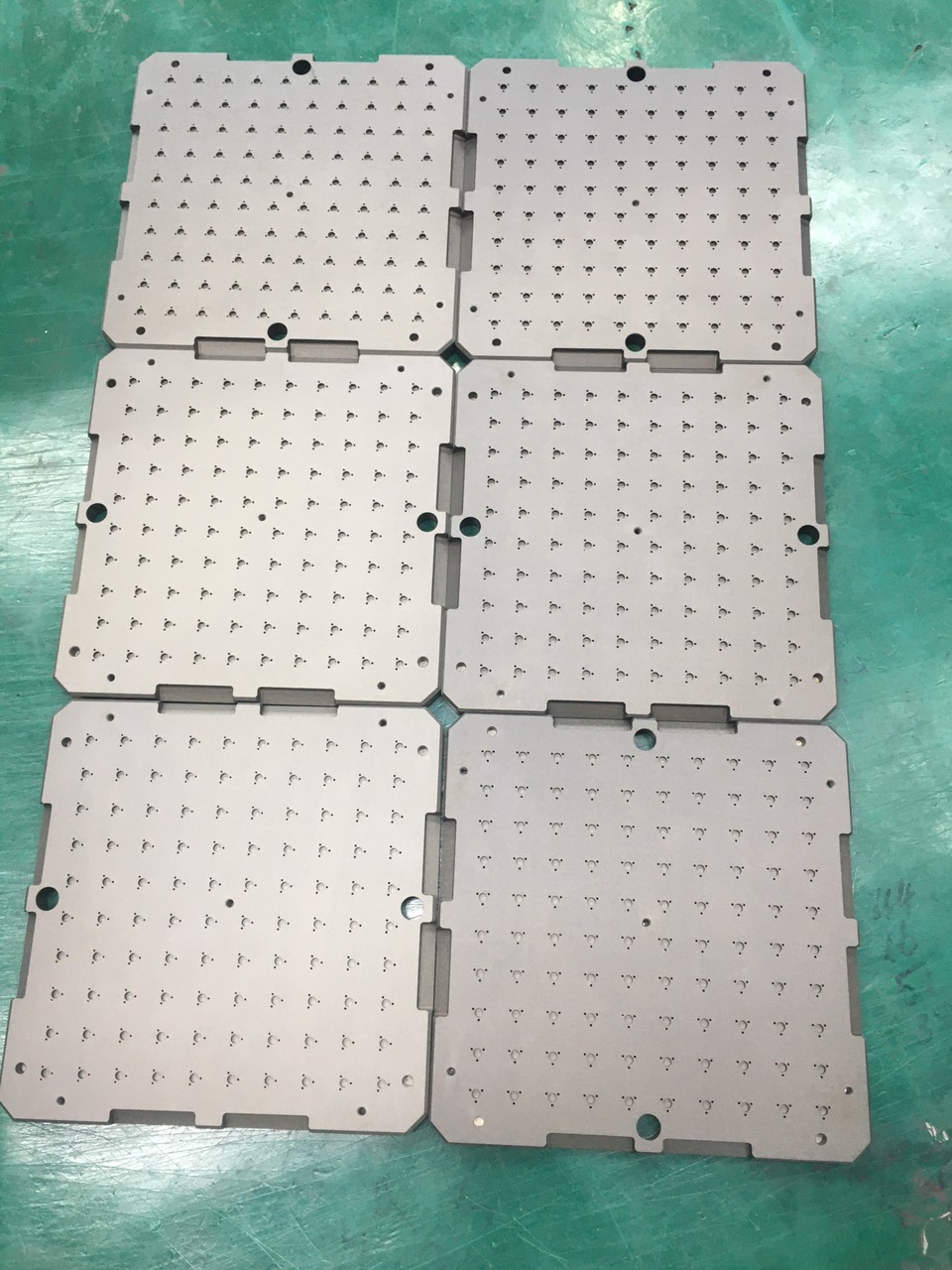

- Insulation Plates

- Blast Shields

You are the 1259206 visitor