ASAHI PLATING VIET NAM.,. JSC

Factory 1: Lot 6-2 Quang Minh Industrial Park , Quang Minh Town, Me Linh Dist, Ha Noi City. Tel 093 200 6371

Factory 2: Lot CN12-01, Yên Phong Industrial Park , Thụy Hòa Commune , Yên Phong Dist, Bắc Ninh Province. Tel 091 589 3753

Commercial Anodizing

Anodizing is a conversion of the aluminum surface to practically pure aluminum oxide: the anodic coating (a true ceramic). Type II is of particular interest to the designer wishing to extol both the virtues of form and function. Allowing for radiant colors; full coverage; full coverage. This anodic coating is significantly more abrasion and corrosion resistant then the untreated metal. This coating may be subsequently dyed in a variety of colors, imparting a very decorative finish both in a satin and a polished surface result. Limitations to these virtues vary according to the alloy and fab method. The casting alloys being the most difficult to work with.

Sulfuric acid anodizing has been defined as “an electrochemical process that intentionally forms a porous anodic oxide on aluminum”. This oxide, an integral part of the metal, is formed when a current is applied to the aluminum parts in a sulfuric acid anodizing bath.

Type II anodizing is by far the most popular form of anodizing aluminum. Everything from high rise buildings to space ships has either been completely anodized or has anodized components as part of their makeup.

Under normal circumstances, the aluminum is anodized using a prescribed set of parameters:

Typically, Type II anodizing is performed in a sulfuric acid bath containing 180-200 grams per Liter of acid and a small amount of dissolved aluminum. The operating temperature is controlled between 68-72º F. Current densities can range from 5-18 amps per square foot (ASF), but commonly are run at 12-15 ASF.

The power supply is a DC rectifier. The aluminum part being anodized is made the anode (or positive pole) in the system. The most efficient cathodes (or negative pole) are 6063t6 aluminum.

Current is applied to the system for a prescribed time, and at the desired current density to achieve the oxide thickness required (oxide thicknesses can range from 0.1 mil to 0.8 mil). The resulting porous oxide can then be colored or sealed.

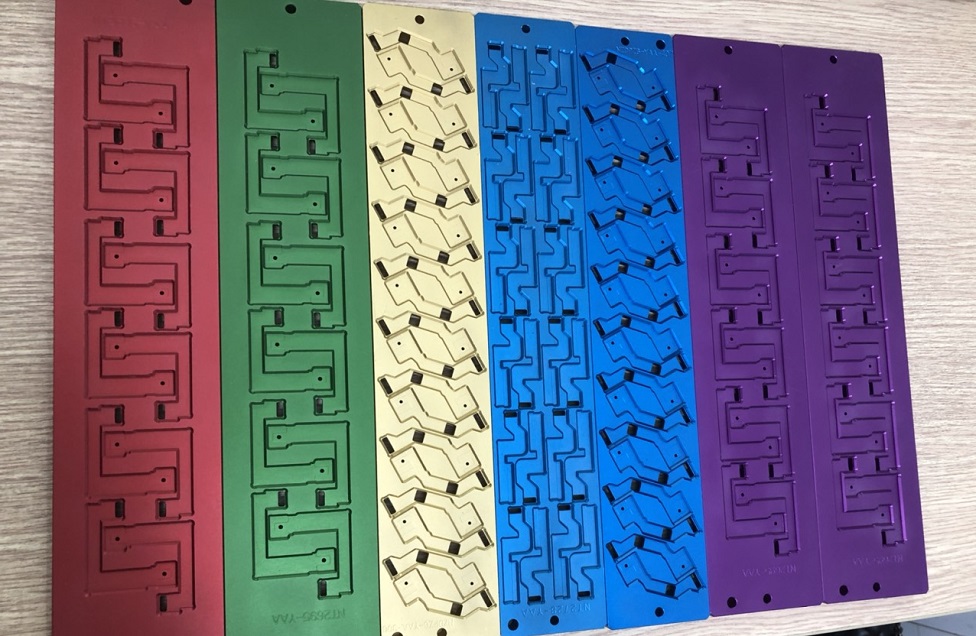

The sulfuric acid process is the most common method for anodizing. The sulfuric acid anodize process films range from .0001"-.001" thick. The overall thickness of the coating formed is roughly 60 percent penetration in the substrate and 40 percent growth over the original dimension of the part (alloy dependent). It is particularly suited for applications where hardness and resistance to abrasion are required. However, where parts are subjected to considerable stress, (such as aircraft parts), the possible presence of the corrosive acid residue is undesirable. The porous nature of sulfuric acid films prior to sealing is significantly useful in the development of colored surface finishes on aluminum and its alloys. The porous aluminum oxide absorbs organic dyes well, and subsequent sealing helps to prevent color loss in service. Although dyed anodized films are reasonably colorfast, they have a tendency to bleach under prolonged direct sunlight. Anoplate currently offers the following colors for commercial customers: Black, Red, Blue, Green, Coyote Brown, Urban Grey, and Gold. Anoplate has the capability of treating the aluminum parts either chemically or mechanically prior to anodizing to achieve a matte (non-reflective) finish.

ASAHI PLATING can certify this finish to MIL-A-8625 Type II both Class 1 and Class 2, as well as many unique customer specifications.

Sulfuric Acid Anodize Features:

- Less expensive than other types of Anodize

- More alloys can be finished

- Harder than chromic anodize

- Clearer finish permits dying with a greater variety of colors

Sulfuric Acid Anodize Applications:

- Optical components

- Medical device components

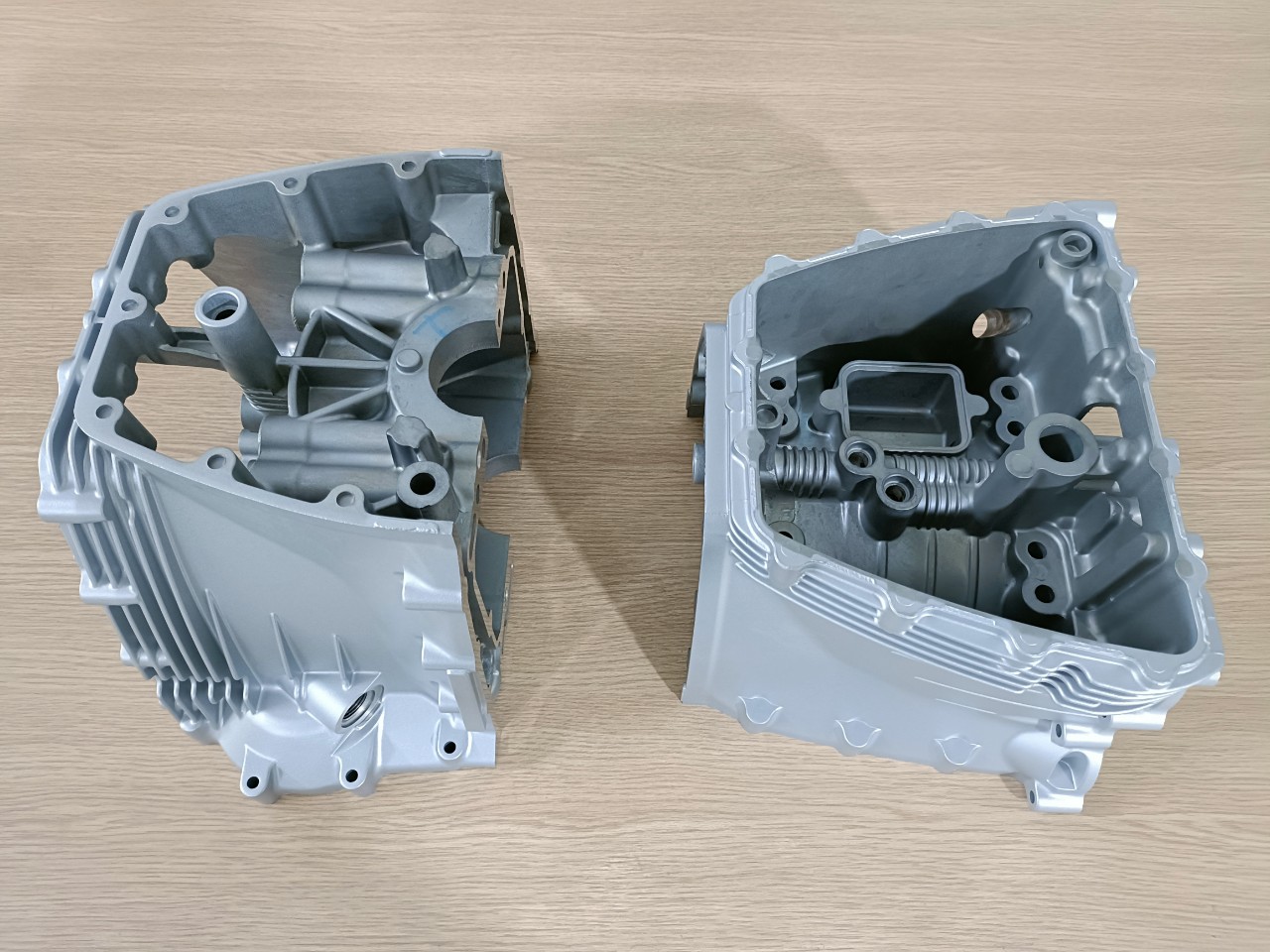

- Hydraulic valve bodies

- Military weapons

- Computer and electronic enclosures

You are the 1259206 visitor